OSHA and Workplace Safety: Industry-Specific Standards Explained

Safety

Dec 11, 2025

Magdalena Rucińska

Content Specialist

The Occupational Safety and Health Administration (OSHA) safeguards millions of workers across the United States by implementing comprehensive safety standards, enforcing regulations, and providing education programs. Discover core OSHA standards and their role in today's workplace safety.

What is OSHA?

The Occupational Safety and Health Administration (OSHA) is a federal agency within the U.S. Department of Labor, dedicated to ensuring safe and healthy working conditions for all employees nationwide. Established by the Occupational Safety and Health Act of 1970, OSHA has the authority to create and enforce workplace safety regulations.

The agency’s enforcement authority includes:

conducting workplace inspections,

issuing citations and penalties for violations,

requiring employers to correct identified hazards to protect worker safety.

OSHA's role and mission

OSHA’s primary mission is to eliminate workplace hazards that cause occupational injuries and illnesses. The agency has a legal responsibility to ensure every worker has a safe workplace free from known risks, like falls, machine accidents, or harmful chemicals. It also deals with safety issues like ergonomic problems and controlling the spread of diseases at work.

Since OSHA was established, it has helped to lower the number of workers dying on the job from about 14,000 each year before 1971.

Throughout its history, OSHA has operated numerous training, compliance assistance, and safety recognition programs to advance its mission.

Through its comprehensive approach, OSHA addresses:

physical safety hazards like falls and machinery accidents,

health hazards, including exposure to hazardous chemicals,

emerging workplace concerns such as ergonomics and infectious disease control.

OSHA works both to enforce safety rules and to teach businesses how to create effective health and safety programs to prevent workplace injuries and illnesses.

How is OSHA organized across the U.S.?

Federal OSHA operates through 10 regional offices across the United States, each responsible for enforcing workplace safety standards within its geographic area. However, not all states rely on federal OSHA for enforcement. Under the OSH Act, states can establish their own occupational safety and health programs—known as State Plans—as long as they are "at least as effective" as federal OSHA. Currently, 22 states and jurisdictions operate approved State Plans covering both private and public sector workers, while several others cover only state and local government employees.

OSHA safety standards by industry

OSHA organizes its workplace safety regulations into four main industry categories, each designed to address sector-specific hazards. Understanding which standards apply to your operations is the first step toward compliance.

General industry

Standards in 29 CFR 1910 apply to the widest range of workplaces in the United States—covering everything from manufacturing plants and warehouses to healthcare facilities and office buildings. Because most employers fall under this category, 29 CFR 1910 is often considered the foundation of OSHA compliance. These regulations are organized into subparts that address specific hazard categories:

Subpart D – Walking-Working Surfaces: Requirements for floors, platforms, ladders, and fall protection systems to prevent slips, trips, and falls.

Subpart E – Exit Routes and Emergency Planning: Standards for emergency action plans, fire prevention, and safe evacuation procedures.

Subpart G – Occupational Health and Environmental Control: Covers ventilation, noise exposure limits, and ionizing radiation.

Subpart H – Hazardous Materials: Regulations for handling flammable liquids, compressed gases, and explosives.

Subpart I – Personal Protective Equipment (PPE): Requirements for eye, face, head, foot, and hand protection, including hazard assessments.

Subpart J – General Environmental Controls: Includes the Lockout/Tagout (LOTO) standard for controlling hazardous energy during equipment servicing.

Subpart L – Fire Protection: Portable fire extinguishers, fixed suppression systems, and fire brigades.

Subpart O – Machinery and Machine Guarding: Safeguards for mechanical power presses, woodworking equipment, and abrasive wheels.

Subpart S – Electrical: Electrical safety requirements for wiring, equipment, and work practices.

Subpart Z – Toxic and Hazardous Substances: Permissible exposure limits (PELs) for airborne contaminants and the Hazard Communication Standard (HazCom).

For most workplaces, the Hazard Communication Standard (1910.1200), lockout/tagout procedures (1910.147), and PPE requirements (1910.132-138) are among the most frequently cited and applicable regulations.

Construction

Construction standards in 29 CFR 1926 address the elevated risks inherent in building, renovation, and demolition work. The construction industry consistently ranks among the most hazardous sectors, with falls, struck-by incidents, electrocutions, and caught-in/between hazards—known as the "Fatal Four"—accounting for the majority of worker fatalities. Key subparts include:

Subpart C – General Safety and Health Provisions: Employer responsibilities, safety training, and housekeeping requirements.

Subpart E – Personal Protective and Lifesaving Equipment: Head, eye, respiratory, and fall protection gear specific to construction environments.

Subpart K – Electrical: Temporary wiring, ground-fault protection, and electrical safety for construction sites.

Subpart L – Scaffolds: Design, erection, and use of scaffolding systems, one of the most frequently cited standards.

Subpart M – Fall Protection: Requirements for guardrails, safety nets, and personal fall arrest systems when working at heights above 6 feet.

Subpart N – Helicopters, Hoists, Elevators, and Conveyors: Safe operation of material handling equipment.

Subpart O – Motor Vehicles, Mechanized Equipment, and Marine Operations: Equipment safety on construction sites.

Subpart P – Excavations: Trenching safety, protective systems, and soil classification to prevent cave-ins.

Subpart CC – Cranes and Derricks: Operator certification, load limits, and inspection requirements.

Fall protection (1926.501) and scaffolding (1926.451) consistently appear among OSHA's top 10 most cited violations each year, making them priority areas for construction employers.

Maritime

Maritime OSHA standards address the unique hazards found in shipyards, marine terminals, and longshoring operations. These environments present distinct risks—from confined spaces aboard vessels to heavy cargo handling on docks—that require specialized regulations. The maritime standards are divided into three parts:

29 CFR 1915 – Shipyard Employment

Covers ship repair, shipbuilding, and shipbreaking activities. Key areas include:Confined and enclosed space entry procedures

Welding, cutting, and hot work safety

Surface preparation and preservation (coatings, blasting)

Fire protection aboard vessels

Personal protective equipment for maritime workers

29 CFR 1917 – Marine Terminals

Addresses hazards at facilities where cargo is loaded, unloaded, and handled. Regulations cover:

Cargo handling equipment (cranes, forklifts, conveyors)

Walking and working surfaces on terminal docks

Vehicle safety and traffic control

Hazardous atmospheres and fumigated cargo

29 CFR 1918 – Longshoring

Focuses on the loading and unloading of vessels, including:Gear certification and cargo handling equipment

Hatch covers and vessel access

Hazardous cargo operations

Fall protection during stevedoring activities

Workers in maritime industries face risks that combine elements of construction, manufacturing, and transportation—making comprehensive safety programs essential.

Agriculture

Agricultural OSHA standards in 29 CFR 1928 protect workers in farming and related operations. While agriculture has historically had limited OSHA coverage compared to other industries, certain standards apply to protect farmworkers from serious hazards.

Key regulations include:

Rollover Protective Structures (ROPS): Tractors manufactured after 1976 must have ROPS and seatbelts to prevent crush injuries during rollovers—one of the leading causes of death in agriculture.

Guarding of Farm Field Equipment: Requirements to protect workers from moving parts on machinery like combines, balers, and augers.

Pesticide and Chemical Safety: While the Environmental Protection Agency (EPA) regulates pesticide application under the Worker Protection Standard, OSHA's Hazard Communication Standard also applies to agricultural chemical handling.

Field Sanitation (1928.110): Employers with 11 or more hand laborers must provide drinking water, toilet facilities, and handwashing stations in the field.

Temporary Labor Camps (1910.142): Housing provided to agricultural workers must meet standards for sanitation, shelter, and safety.

Logging Operations (1910.266): While not exclusively agricultural, logging standards often intersect with farm forestry operations.

It's important to note that small farming operations—particularly family farms with no outside employees—have significant exemptions from OSHA enforcement. However, larger agricultural employers and those using temporary or migrant workers must comply with applicable standards.

How many OSHA standards are there?

OSHA maintains nearly 1,000 individual standards distributed across its four main industry categories. For most employers and workers, the standards in 29 CFR 1910 (general industry) will be the most relevant, as these regulations apply to the broadest range of workplaces—from manufacturing facilities and warehouses to offices and retail establishments.

OSHA standards are regulatory requirements codified in Title 29 of the Code of Federal Regulations. It is a careful process that includes extensive research, gathering feedback from diverse stakeholders, and allowing the public to share their views. This helps make sure new rules protect workers and are practical for workplaces to follow.

Which standards apply to your workplace?

Many employers find that multiple OSHA standards apply to their operations.

A food processing plant, for example, may need to follow general industry standards (1910) for most activities, but construction standards (1926) during facility renovations.

Understanding this overlap is crucial for maintaining compliance across all work activities.

How does OSHA enforce workplace safety?

OSHA doesn't just set standards—it actively enforces them through workplace inspections conducted by compliance safety and health officers. An inspection can happen for several reasons: an employee files a complaint, a serious injury or fatality occurs, another agency makes a referral, or the workplace falls within a high-hazard industry targeted for routine checks.

During an inspection, officers walk through the facility, review safety programs and records, observe work practices, and talk with employees to get a complete picture of conditions on the ground. If hazards or violations are found, the employer is notified and given a timeframe to correct the issues.

What happens when OSHA finds violations?

When inspectors identify violations, OSHA issues citations that describe the problem and assign penalties based on severity. Serious violations—those that could result in death or significant physical harm—carry substantial fines. Willful violations, where an employer knowingly ignores safety requirements, or repeated violations of the same standard result in even steeper penalties.

OSHA can also cite employers under the General Duty Clause, which applies when no specific standard exists but the hazard is well-recognized in the industry. This ensures employers can't escape responsibility simply because a rule hasn't been written yet.

Employers who disagree with a citation have the right to contest it through the Occupational Safety and Health Review Commission (OSHRC)—an independent federal agency that adjudicates disputes between OSHA and employers. This appeals process helps ensure that enforcement remains fair and evidence-based.

What training does OSHA provide?

Beyond enforcement, OSHA invests heavily in education to help employers and workers prevent hazards before they lead to injuries. The OSHA Training Institute serves as the agency's primary educational hub, offering courses that range from basic hazard recognition and workers' rights to advanced certifications for safety professionals.

OSHA’s well-known 10-Hour and 30-Hour training programs offer safety lessons for workers and supervisors. Both are available in construction and general industry tracks. Participants can complete them online or in person through OSHA-authorized providers. Upon completion, workers receive a Department of Labor certification—a credential many employers now require.

💡 Good to know:

The Susan Harwood Training Grant Program extends OSHA's educational reach by funding nonprofits, labor unions, and employer associations to develop and deliver targeted safety training. These grants prioritize underserved worker populations—including those with limited English proficiency, temporary workers, and employees in high-hazard industries who may lack access to formal training. The training is free and offered in many languages so that all workers can learn how to stay safe, no matter their background.

Workplace injuries and illnesses: Where do we stand?

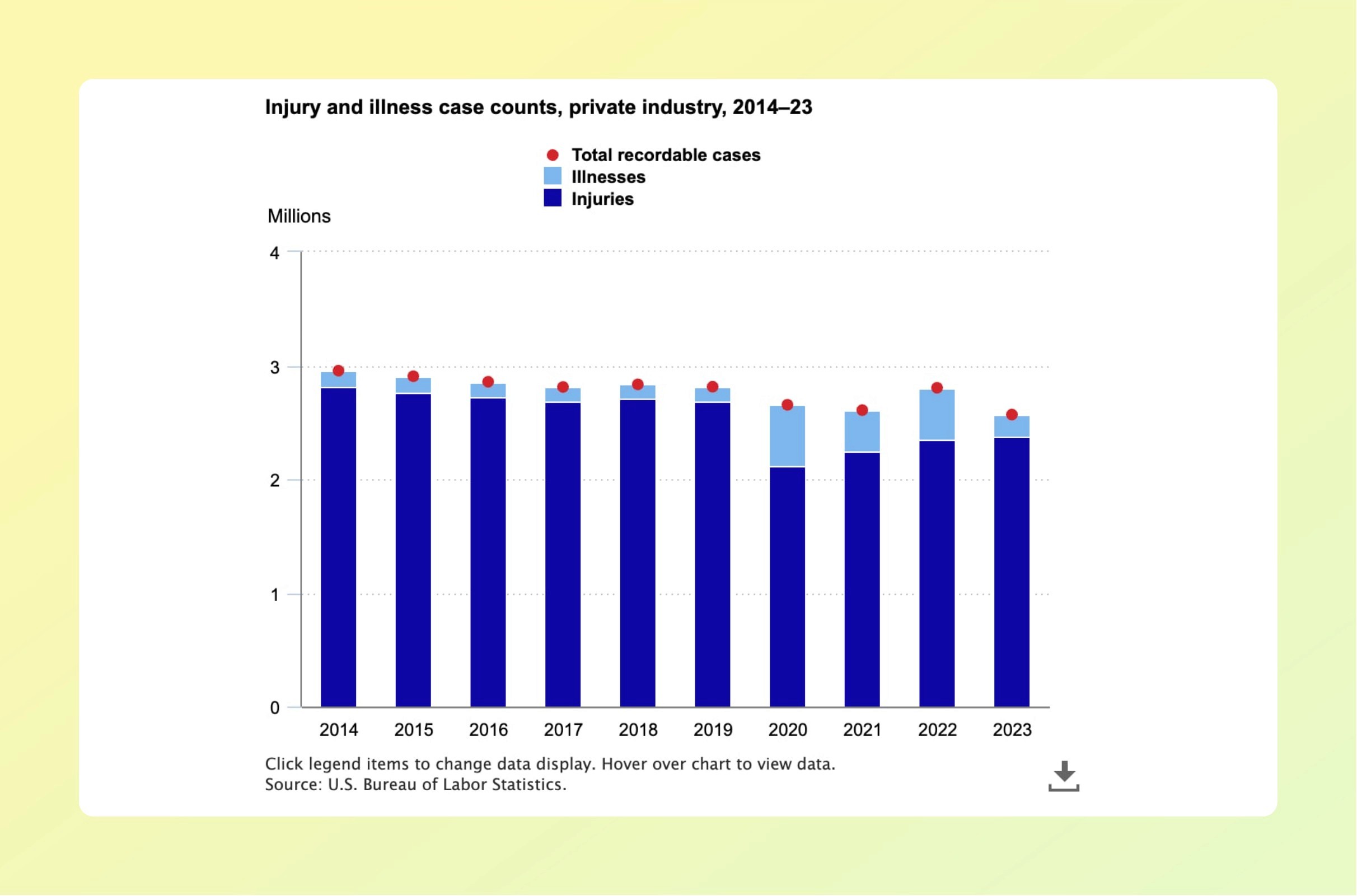

OSHA has made significant strides in improving workplace safety since 1970, but millions of workers are still getting hurt on the job each year. In 2023, private industry employers reported 2.6 million nonfatal workplace injuries and illnesses—an 8.4 percent decrease from the previous year, according to the U.S. Bureau of Labor Statistics. The overall incidence rate fell to 2.4 cases per 100 full-time equivalent workers, marking the lowest level recorded since 2003.

Source: Bureau of Labor Statistics, U.S. Department of Labor

Much of this improvement came from a sharp decline in workplace illnesses. Illness cases dropped 56.6 percent to 200,100—the fewest reported since 2019. Respiratory illnesses, which surged during the COVID-19 pandemic, saw the steepest decline: down 72.6 percent from 365,000 cases in 2022 to just 100,200 in 2023.

The trend is encouraging, but context matters. Nearly 2.4 million workers were injured in 2023 alone—each case representing a real person who went to work and came home hurt. That's why OSHA's continued enforcement of 29 CFR 1910, 29 CFR 1926, and other industry-specific standards remains critical to driving these numbers down further.

Comply with OSHA standards using Parakeet Risk 🦜

Ensuring compliance with OSHA standards is essential for maintaining safe working conditions and protecting workers across various industries.

Parakeet Risk offers solutions to help industrial environments efficiently meet OSHA requirements. The platform provides compliance assistance and support services that help businesses identify workplace hazards, manage risks, and maintain up-to-date safety programs. Employers can access training materials, track certifications, and monitor progress at their own pace, ensuring thorough completion of all necessary safety protocols.

Contact our team to learn how you can streamline OSHA compliance, reduce the risk of citations and penalties, and ensure safe working conditions.