Industrial Third-Party Risk Assessment: A Complete Guide for Manufacturing, Construction, and Logistics

Risk Management

Jan 12, 2026

Magdalena Rucińska

Content Specialist

When contractors, subcontractors, and suppliers work on your sites or in your supply chain, their risks become your risks. Systematic third-party risk assessment protects your people, operations, and the whole organization. Find out how to identify, evaluate, and manage the threats before they become real incidents.

What Is Third-Party Risk Assessment?

Every contractor, subcontractor, and supplier you bring onto your industrial site carries risk. A scaffolding crew without proper fall protection training, a logistics carrier with poor vehicle maintenance, or a parts supplier on the verge of bankruptcy—each represents a potential threat to your bottom line.

Unlike general risk assessment, which might focus on internal processes or equipment, third-party assessment examines risks you don’t directly control. For instance:

❌ a maintenance contractor’s safety culture,

❌ a supplier’s financial stability,

❌ or a trucking company’s driver training programs

The above examples fall outside your immediate oversight. Yet their failures become your problems when they occur on your watch.

The risk assessment process typically begins during prequalification—before you even award a contract. During this phase, you assess risk by gathering data on safety records, certifications, insurance coverage, and financial health. Onboarding extends this evaluation with site-specific requirements: inductions, competency verification, and document collection.

Why Is Third-Party Risk Assessment Important?

In high-stakes industrial environments, risk assessment is absolutely essential for your operations. What happens when you fail to properly vet third parties? Inadequate third-party risk assessments can lead to costly regulatory penalties and liability for incidents you didn’t cause.

Workplace accidents carry tremendous costs. When a contractor suffers a serious injury on your site, the investigation begins immediately. Did you verify their training, check their safety record, and ensure proper supervision? Conducting a thorough risk assessment shows due diligence, while its absence can lead to liability that insurance may not fully cover.

Regulatory compliance is non-negotiable. OSHA's Multi-Employer Citation Policy can hold host employers liable for contractor violations. DOT regulations oversee carrier qualifications, while EPA rules apply to waste handling. The risk assessment process helps ensure you meet these obligations and identifies gaps before regulators do.

🔍 Discover how regulatory compliance protects your workforce and reduces operational risks: Understanding Safety Compliance: Key Concepts and Effective Strategies

Project delays cost money. A contractor who fails to deliver disrupts schedules, and a financially unstable supplier can halt production. Identifying risks during prequalification helps avoid surprises during the project.

Reputation damage spreads quickly. When a subcontractor violates labor laws or causes environmental incidents, your company gets mentioned in the headlines. Public health risks, safety failures, and ethical violations by third parties become your reputational problem.

⚖️ Find out how to build ethics strategy: Integrating Ethics Strategy for Resilient and Compliant Business

Supply chain resilience requires proactive assessment. COVID-19 demonstrated how quickly supply chains can collapse. Organizations that had assessed supplier risks, identified alternatives, and developed contingency plans recovered faster than those who hadn’t considered these operational risks.

🛠️ Prepare for supplier disruptions and capacity constraints: 2025 Supply Chain Manufacturing Outlook

Risk assessment helps organizations protect people, maintain operations, and meet legal obligations. This process mitigates uncertainties associated with third-party relationships and fosters cooperative business partnerships.

🛡️ Protect against digital threats in your vendor network: The Supply Chain Cybersecurity Challenge

Types of Third-Party Risk Assessment

Effective programs assess various risks and hazards. They use appropriate methods to evaluate each type of risk.

Safety and Compliance Risk

Safety assessments check if contractors can do their work without putting people at risk. This includes reviewing:

Incident statistics and safety records. The Total Recordable Incident Rate (TRIR), lost-time injury rate, and serious incident history help us understand safety performance. For example, a scaffolding company with several fall incidents needs closer examination compared to a company with no incidents.

🧩 Understand regulatory requirements for manufacturing, construction, and logistics: OSHA and Workplace Safety: Industry-Specific Standards Explained

Certifications and training programs. Do workers hold required licenses? Has the company completed necessary safety training? For high-risk jobs—like entering confined spaces, working with hot materials, or working at heights—specific skills must be checked before starting any task.

Safety management systems. Having written safety programs, ways to identify hazards, and procedures for investigating incidents shows that the organization cares about worker safety. ISO 45001 certification confirms these systems have been properly reviewed.

⚡ Read about ISO 50001: The Standard Powering a Sustainable Future

Insurance and workers’ compensation. Adequate coverage protects both the contractor’s workers and your organization from financial consequences of incidents.

💡 Parakeet's tip:

Use a simple scoring system to evaluate safety performance. A semi-quantitative scoring approach works well here! Assign numbers to different safety factors and decide how important each factor is. Then, calculate a total score for each contractor. If a contractor scores above a certain level, they can proceed with normal safety measures. If they score below this level, they will be closely monitored or not accepted.

Operational Risk

Operational assessment evaluates whether contractors can deliver what they promise:

Capacity and resource availability. Can they actually perform the work required? Do they have sufficient equipment, personnel, and expertise.

Performance history. Past project delivery, quality metrics, and customer references reveal actual capabilities versus marketing claims.

Control measures and quality processes. Documented procedures, inspection protocols, and quality management systems reduce the likelihood of defective work.

Contingency plans for disruptions. What happens if key equipment fails? If critical personnel become unavailable? Contractors with backup plans represent lower operational risks than those operating without margins.

👁️ Track, prioritize, and manage third-party threats systematically: Essential Guide to Using a Risk Register

Financial Risk

A financial assessment evaluates whether third parties can maintain their business relationships.

Stability indicators. Credit ratings, financial statements, and payment histories reveal whether a supplier might suddenly fail or a contractor might abandon a project.

Bonding capacity. For construction and major service contracts, bonding provides security against non-performance.

Insurance adequacy. General liability, professional indemnity, and umbrella coverage should match the potential consequences of work performed.

Cash flow considerations. Suppliers under financial stress may cut corners on quality or safety to reduce costs—increasing your risk even before outright failure occurs.

✅ Stay ahead with emerging audit technologies and methodologies: Top Trends Transforming Risk Audit

Environmental and Regulatory Risk

Environmental assessment covers compliance with regulations governing waste, emissions, and site impacts:

Permit status and compliance history. Have they maintained required environmental permits? Any violations or enforcement actions?

Waste management practices. For contractors handling hazardous chemicals or generating waste on your site, proper disposal procedures prevent contamination and regulatory penalties.

Environmental certifications. ISO 14001 certification indicates systematic environmental management, though self-reported practices also warrant review.

Corrective action history. Past violations aren’t necessarily disqualifying, but the response matters. Did they implement effective corrective measures?

A comprehensive risk matrix helps prioritize across these categories, plotting likelihood against severity to identify which potential hazards demand immediate attention and which represent acceptable, managed risks.

🌱 Integrate environmental and social criteria into contractor selection: Top ESG and Sustainability Trends Shaping Industries in 2025

Challenges of Third-Party Risk Assessment

Performing effective third-party risk assessments poses significant challenges for industrial organizations:

Volume overwhelms capacity

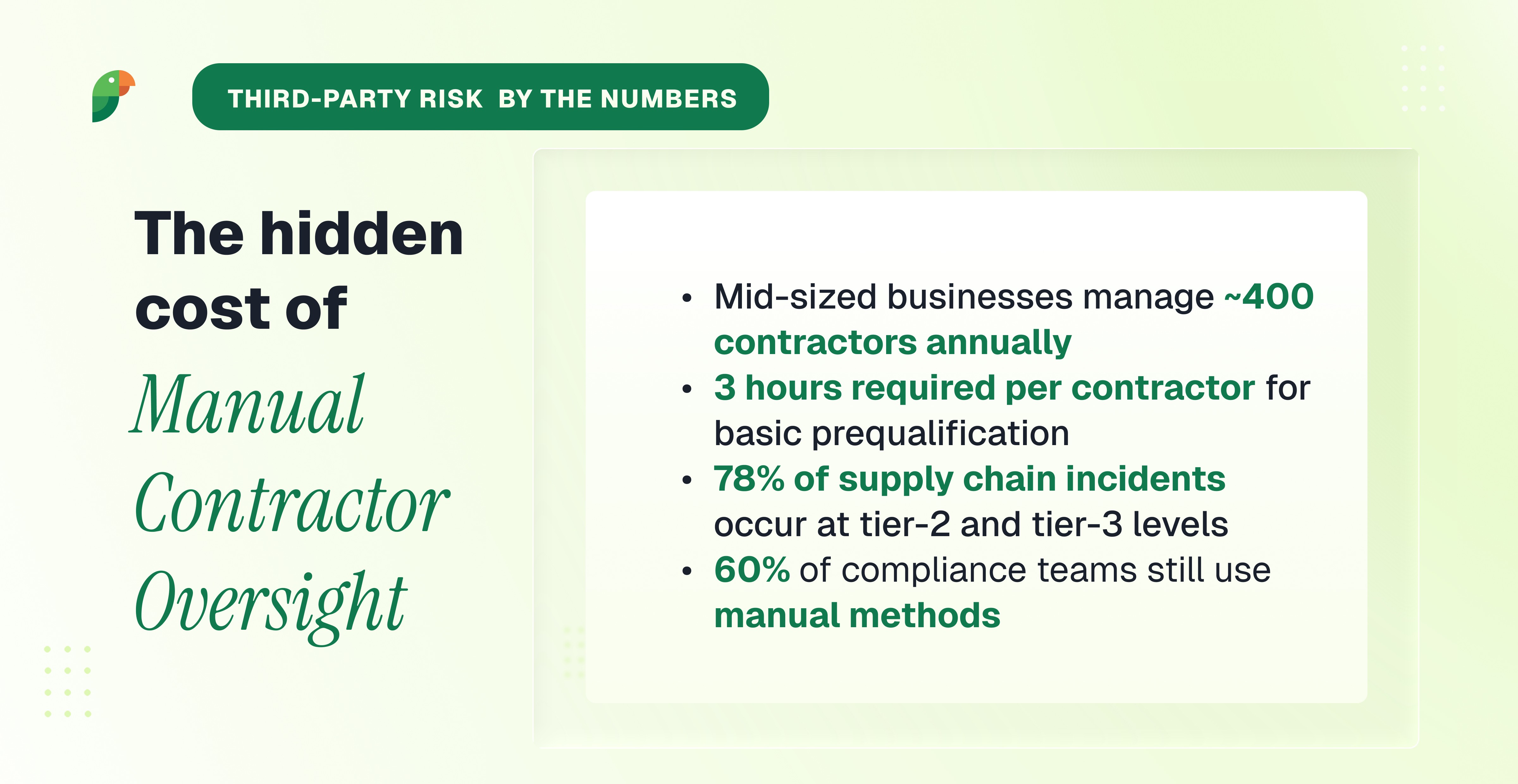

Even mid-sized manufacturers and construction firms face overwhelming contractor volumes.

A regional manufacturing facility might juggle 50-100 contractors each year, while a medium-scale construction project can involve 15-30 subcontractors with their own network of suppliers.

For smaller companies without dedicated compliance teams, tracking this through spreadsheets and email chains becomes a full-time job. One safety manager often handles what should require an entire department. They're buried in insurance certificates, training records, and compliance documents—constantly following up on expired credentials instead of conducting meaningful risk assessments. The manual chaos means actual hazards go unnoticed while administrative tasks consume every hour.

Documentation arrives incomplete or inconsistent

Every contractor maintains records differently. Some provide detailed safety statistics; others offer vague assurances. Insurance certificates arrive in various formats. Training records may be outdated or missing entirely. Without standardized requirements and automated validation, gathering the data collected for proper hazard identification becomes a constant struggle.

📖 Find out how to streamline your onboarding process for seamless contractor integration. Read: Contractors Onboarding Invitation Management

Paper-based systems create dangerous gaps

Spreadsheets do not remind you when insurance expires. Important documents can get lost in email chains. Manual processes can lead to mistakes, like a contractor working for months before anyone notices their safety certification has expired. These gaps are the weak points that can cause incidents.

Source: Common Challenges in Contractor Management and How to Solve Them. Alcumus Report.

A conservative estimate to prequalify for just health and safety would be three hours per contractor/supplier. For a mid-size business this could be 1,200 hours of chasing policies.

Subcontractor visibility is limited

Your main contractor might do a great job, but what about their scaffolding subcontractor or that subcontractor’s labor provider? These second- and third-level relationships often have little oversight, but their workers still face the same risks on your site as everyone else.

Time pressure forces shortcuts

When a project deadline is close and you need a specialty contractor right away, you might rush or skip a full assessment. The need to move quickly can clash with the careful process that risk evaluation needs.

Manual contractor management doesn't just waste time—it creates systematic risk. When safety managers spend 1,200 hours annually chasing paperwork instead of evaluating actual hazards, critical threats slip through.

💡 Parakeet's tip:

Automation transforms this dynamic by handling repetitive verification tasks—insurance checks, credential tracking, document collection—freeing your team to focus on what matters: identifying real risks before they cause incidents. The goal isn't replacing human expertise; it's amplifying it by eliminating administrative noise.

How to Perform Third-Party Risk Assessment?

Here’s how to effectively assess third-party risks—without overwhelming your compliance team.

Establish Prequalification Criteria

Before evaluating any contractor, define what you’re looking for. Clear criteria prevent inconsistent decision-making and reduce time spent on unqualified vendors.

Set category-specific requirements

A cleaning contractor faces different potential threats than a crane operator. Define minimum thresholds for safety performance, experience, insurance, and certifications by work type and risk level. High-risk work categories—scaffolding, electrical, confined space, heavy lifting—require more stringent standards than routine maintenance.

Create standardized questionnaires

Develop consistent questions that capture essential qualification data. Ask about incident rates, safety programs, relevant certifications, equipment maintenance, and financial stability. Standardization ensures you gather comparable information across all vendors.

Establish automated scoring systems

Configure your contractor management platform to calculate risk scores automatically based on questionnaire responses and submitted documentation. For example:

TRIR below industry average: +3 points

ISO 45001 certified: +2 points

Any OSHA violations in past 3 years: -5 points

Insurance coverage meets requirements: +2 points

✅ Align your third-party requirements with international quality frameworks: Essential ISO Standards for Manufacturing Companies

Contractors scoring above your threshold proceed automatically; those below trigger manual review. This approach directs human attention where it’s needed most.

Define must-pass criteria

Some requirements aren’t negotiable. No insurance certificate? Application stops. Expired safety certifications? Cannot proceed until renewed. Configure these as hard blocks in your system rather than point deductions.

🔎 Learn systematic approaches to evaluate contractor capabilities before they step on-site: The Ultimate Guide to Contractor Prequalification

Conduct On-Site Evaluations

On-site evaluations are important because they let you see firsthand if contractors are following safety rules and operating standards. For high-risk third-party relationships, physical audits help identify potential hazards that may not be evident through documentation alone.

To make your site assessments effective, focus on these four key areas:

Plan visits to facilities of key suppliers. Before you approve a supplier for important safety parts, go to their site. Watch how they handle quality control, check their equipment, or meet their team face-to-face. Seeing things firsthand shows you what questionnaires might miss.

Verify safety practices in action. When contractors start work, watch how they do their jobs. For example, see if the scaffolding crew uses fall protection and if the electrical team follows lockout/tagout steps. Compare what you see to the written policies.

Talk to supervisors and workers directly. These conversations give you a better sense of the safety culture than just reading management documents. Ask them about recent safety meetings, how they report near-misses, and how they deal with problems.

Record your findings using digital tools. With risk management apps, you can upload files right away to a central system. This avoids paper reports getting lost and makes sure any issues get the right follow-up.

Monitor Ongoing Performance

Prequalification sets the minimum standards for contractors. Ongoing monitoring makes sure they keep meeting those standards over time.

Track both leading and lagging indicators. In addition to incident rates, keep an eye on near-miss reports, safety observations, training completion, and audit results. If a contractor’s leading indicators are getting worse, it could signal bigger problems ahead.

Ask contractors to report regularly. Set clear rules for what they need to report and when. For example, require monthly safety stats, incident notifications within 24 hours, and quarterly performance reviews to keep everyone accountable.

Automate how you track incidents. When something happens with a contractor, record it in your system and link it to their profile. Over time, this creates a record that helps you make better decisions in the future.

Set up clear steps for corrective action. Decide in advance what happens if a contractor does not meet your standards. Small problems might lead to a warning and an improvement plan. Repeated or serious issues could mean suspension or termination. Having these steps ready ensures you enforce rules fairly.

✨ Stay ahead with emerging audit technologies and methodologies: Top Trends Transforming Risk Audit

Maintain Compliance Documentation

Documentation has two main purposes: it guides how you put protective measures in place and shows regulators, insurers, and courts that you have done your due diligence.

Keep all your records in one place. Store assessment records, approval decisions, audit reports, incident logs, and corrective actions in your contractor management system. If an auditor asks about a contractor’s qualifications, you should be able to find the records quickly.

Set up your system to create automated reports. These reports should show contractor status, upcoming expirations, and performance trends. They help with internal reviews and regulatory inspections.

Keep historical records, even after your relationship with a contractor ends. Liability claims can come up years after the work is done. If there is a lawsuit five years later, you will need to show the assessment records you kept.

Review your own process from time to time. Check that your risk assessment steps are being followed. Make sure all contractors complete the required questionnaires and that expired documents trigger the right status changes. These audits help you find and fix problems early.

👤 Address the human factors that impact audit effectiveness: The Hidden Stress of Safety Audits

Continuously Improve Third-Party Risk Assessment

Update your risk assessment methods as you gain experience and as conditions change.

Learn from incidents. When something happens with a contractor, either at your site or in the industry, check if your assessment process would have caught the risk. For example, a major scaffolding accident at another company might show that your prequalification criteria do not fully cover fall protection programs.

Update your criteria when regulations change. New technologies, new rules, and new hazards mean you need to adjust your assessment methods. When OSHA sets new requirements or industry standards change, add these to your evaluation process.

Compare your practices with those of other organizations. Use industry groups, safety forums, and peer networks to see how others assess risks. Ask yourself if others are spotting risks you might be missing or using better methods.

Use analytics to improve your process. Advanced systems can look at contractor performance data to find patterns, such as which types of contractors have more incidents or which qualification factors predict good performance. This helps you decide where to focus your improvement efforts.

🚩 Navigate regulatory changes affecting contractor oversight: OSHA and Workplace Safety After the Government Shutdown

Build a Proportionate, Risk-Based Program

Not every third-party relationship needs the same level of assessment. Proportionality means focusing your attention where it matters most and avoiding extra work for low-risk partners.

🔗 Understand how supplier relationships directly impact manufacturing efficiency and quality: The Role of Supply Chain in Manufacturing Processes

Tier contractors by risk level

A landscaping contractor mowing grass faces different risks than an electrical contractor working on live systems. Create tiers based on the type of work, site access, importance, and past risk patterns. Then, apply the right assessment requirements for each tier.

Low risk: Automated questionnaire, basic document verification, standard insurance requirements

Medium risk: Enhanced questionnaire, reference checks, periodic performance monitoring

High risk: Detailed assessment, site audits, continuous monitoring, executive approval

💎 Learn about federal programs strengthening critical material sourcing: DOE Funding Initiative: $134 Million for Rare Earth Supply Chains

Streamline low-risk relationships

Don’t ask office supply vendors to fill out safety questionnaires designed for heavy construction contractors. Use simpler processes for low-risk vendors to reduce paperwork and avoid frustration.

🚀 Ready to Transform Your Third-Party Risk Management? Parakeet's platform eliminates the administrative burden of contractor management, so your team can focus on strategic risk decisions instead of chasing paperwork. Schedule a Demo! 🦜

Focus resources on high-risk relationships

Scaffolding contractors, crane operators, and sole-source suppliers of critical components deserve significant investment in assessment and monitoring. Manual review, site visits, and ongoing oversight are justified because of the potential consequences if something goes wrong.

🔎 Explore how diverse supplier networks reduce risk and drive innovation: The Essential Guide to Supplier Diversity

Automate the routine, humanize the complex

Systems can take care of document validation, expiration tracking, and score calculation. People are needed to evaluate complex situations, conduct meaningful audits, and make judgment calls on tricky cases. Dividing the work this way makes your process both efficient and effective.

Conclusion

Done well, third-party risk assessment becomes less about paperwork and more about what it’s actually meant to accomplish: ensuring that everyone who works on your sites or contributes to your operations can do so safely, reliably, and in compliance with the standards you’ve established.

Key Takeaways:

✅ Third-party incidents can result in regulatory penalties, liability exposure, and reputational damage

✅ Effective assessment requires evaluating safety, operational, financial, and environmental risks

✅ Risk-based tiering ensures resources focus on high-risk relationships while streamlining low-risk vendors

Have questions about implementing risk-based contractor assessment for your specific operations? Our industrial risk experts are here to help. Get in touch!